Stafl Systems

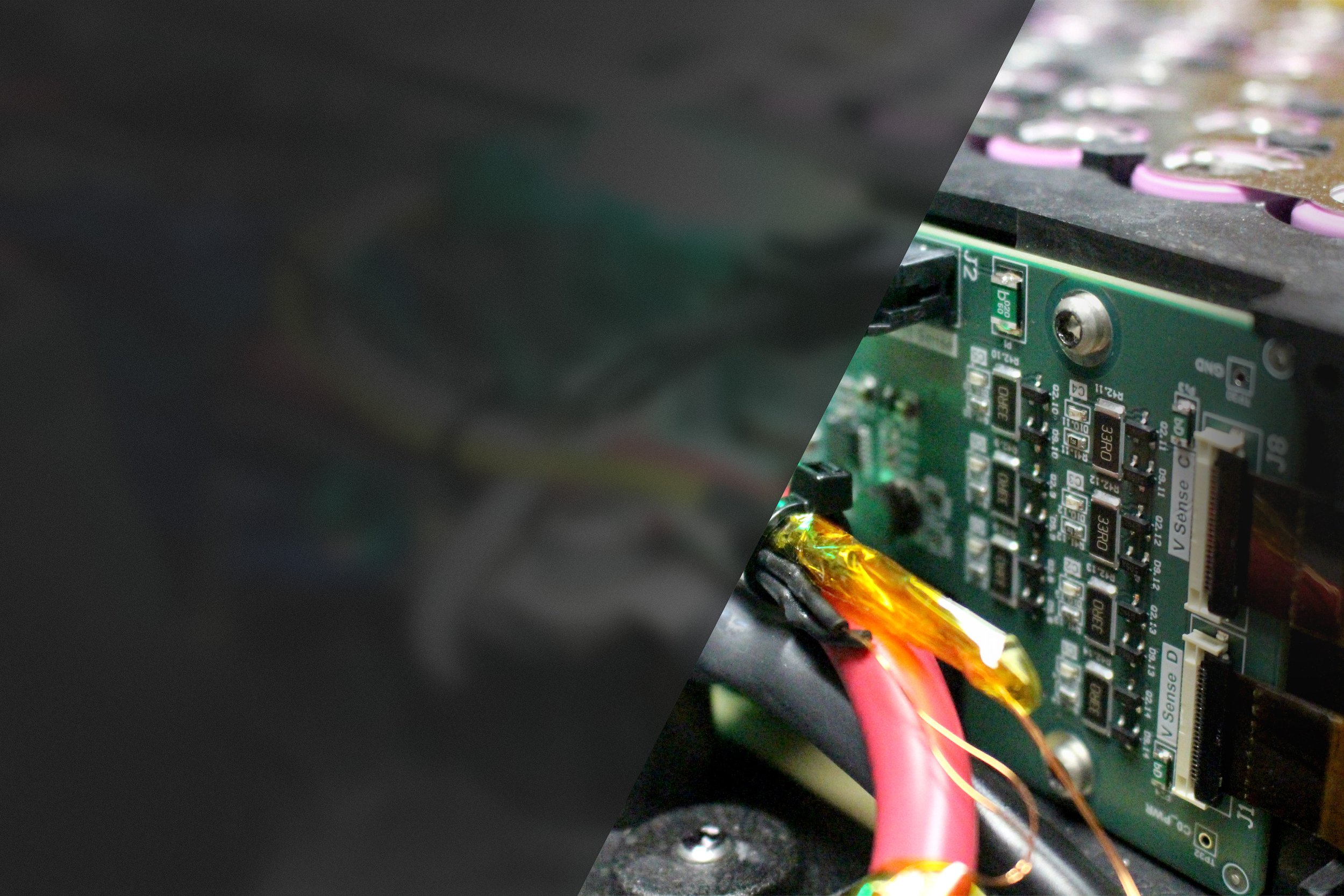

Battery Management Systems

Properly harnessing today’s most sophisticated battery technology.

Lithium-ion batteries require sophisticated management systems to control proper charging and discharging. Properly integrated into a battery pack design, Stafl Systems world-class BMS products ensure long-term, reliable operation.

BMS PRODUCT CATALOG

Stafl Systems Battery Management Systems require one BMS Master Module (e.g. BMS1000M) and 1 to 64 BMS Monitor Modules (e.g. BMS1101S / BMS1102S) to function.

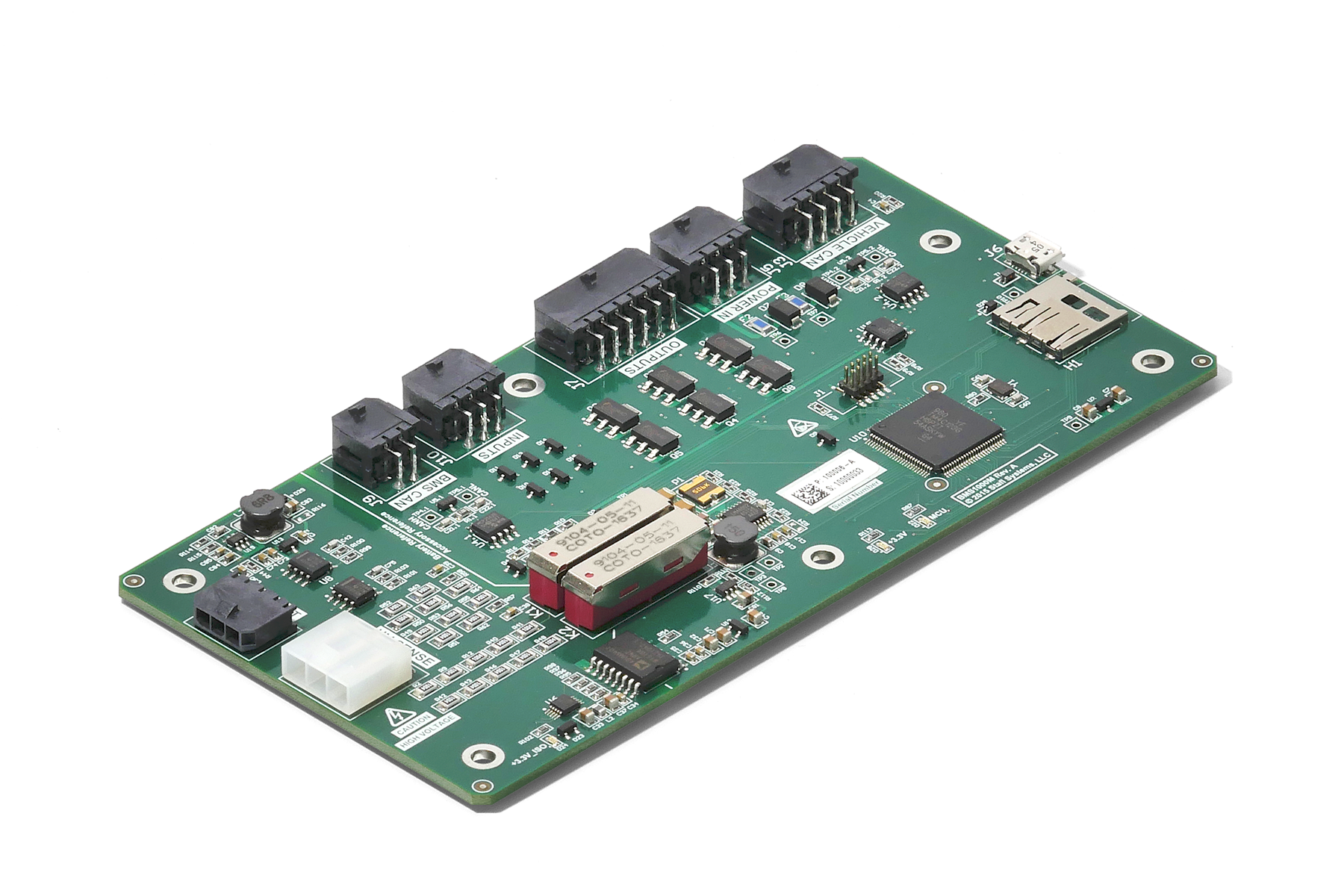

BMS1000M (BMS Master Unit)

For pricing and availability, contact us.

Integrated precharge and main contactor control circuit

Communication with Vehicle Control Unit (VCU) via standard CAN Bus Interface, with multiple supported baud rates

Standard output messages include cell voltages/temperatures, pack voltage/current, and fault flags

Runs internal balancing or commands received from VCU

May be installed externally in appropriately sealed enclosure

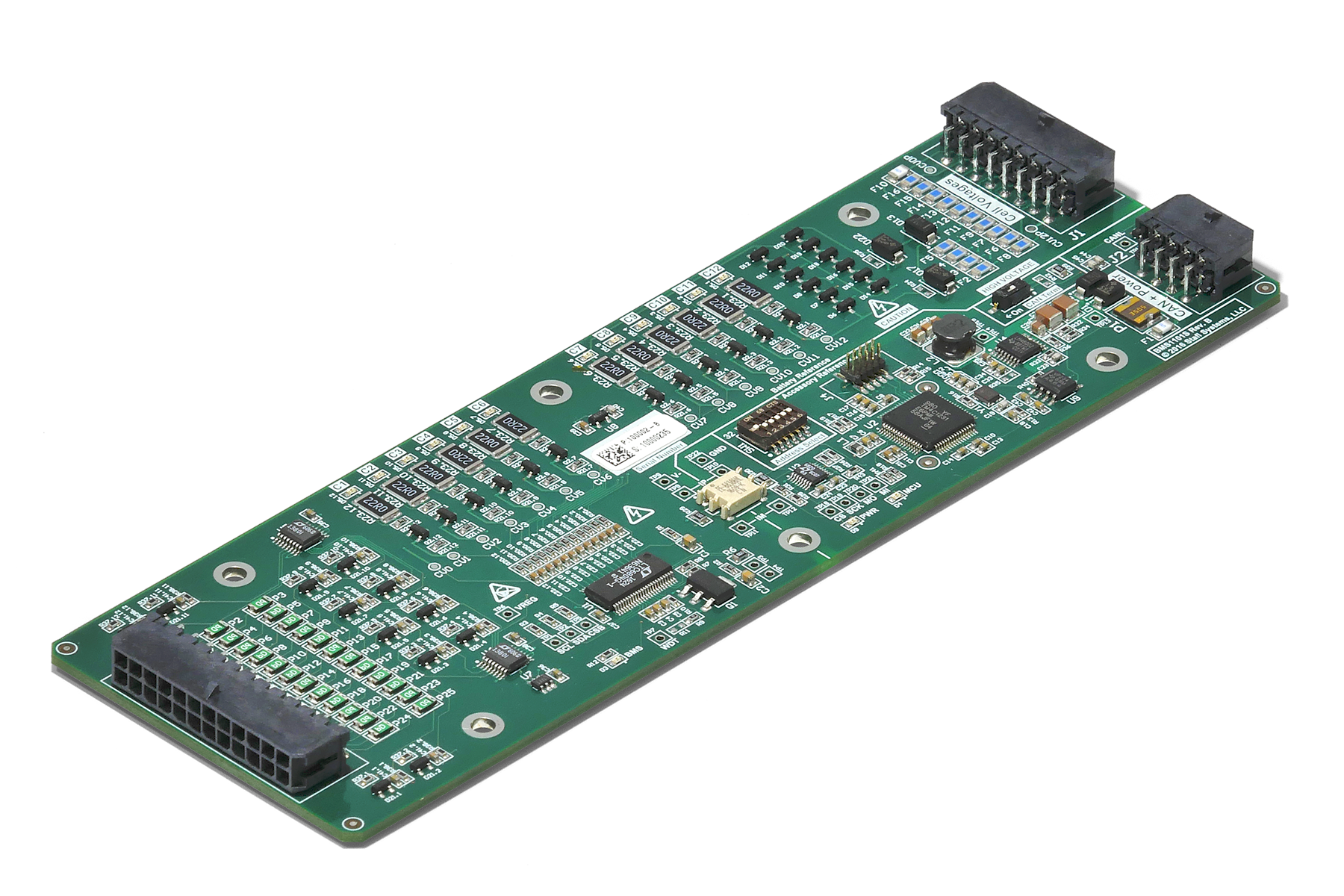

BMS1101S (BMS Monitor Unit)

For pricing and availability, contact us.

Ability to monitor and balance up to 12 series cells

Allows system to be configured for packs with 12-256 series cells

Yields excellent measurement accuracy across common pack conditions

May be installed externally in appropriately sealed enclosure

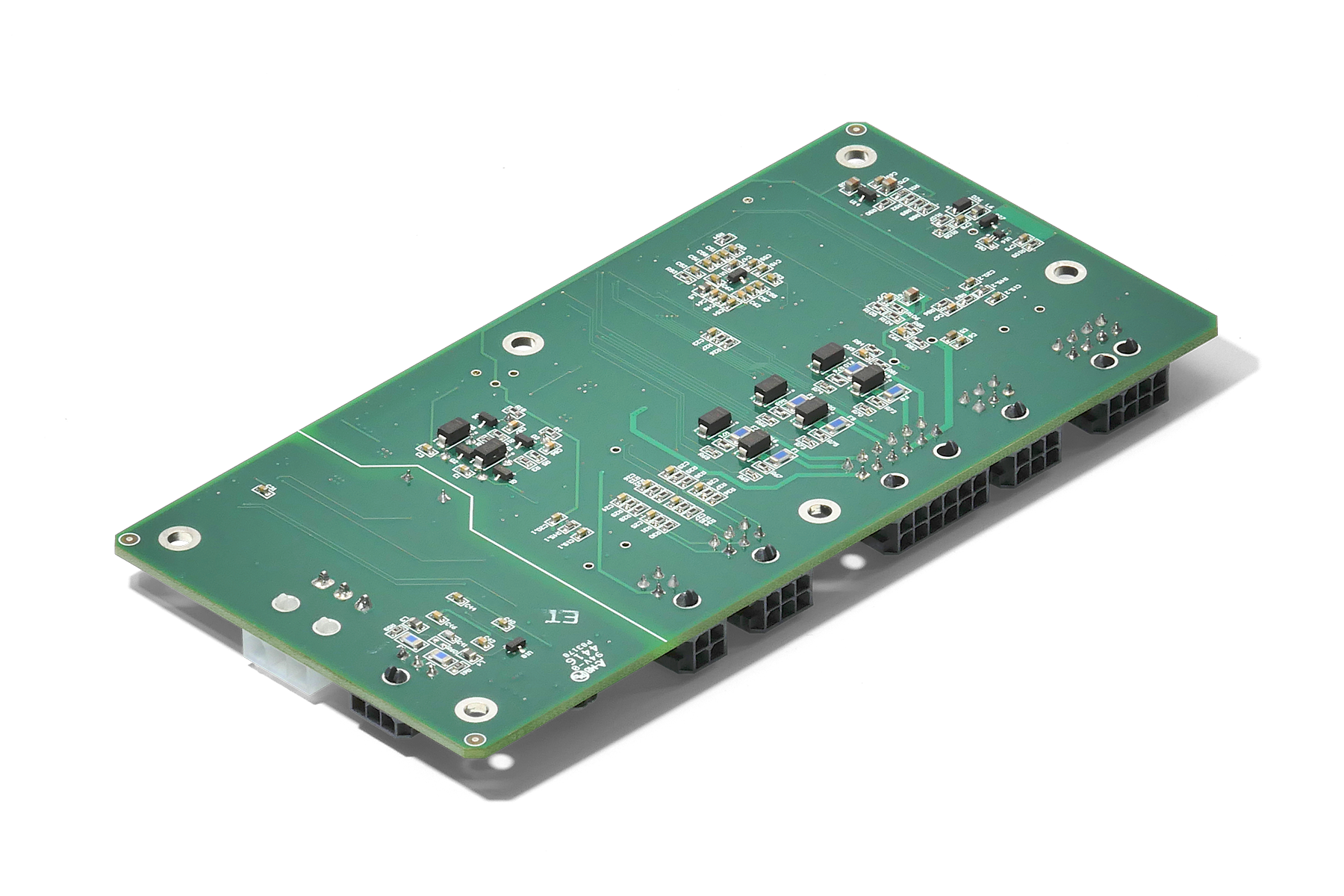

BMS1102S (BMS Monitor Unit)

For pricing and availability, contact us.

Ability to monitor and balance up to 12 series cells

Allows system to be configured for packs with 12-256 series cells

Yields excellent measurement accuracy across common pack conditions

May be installed externally in appropriately sealed enclosure

UNRIVALED ACCURACY

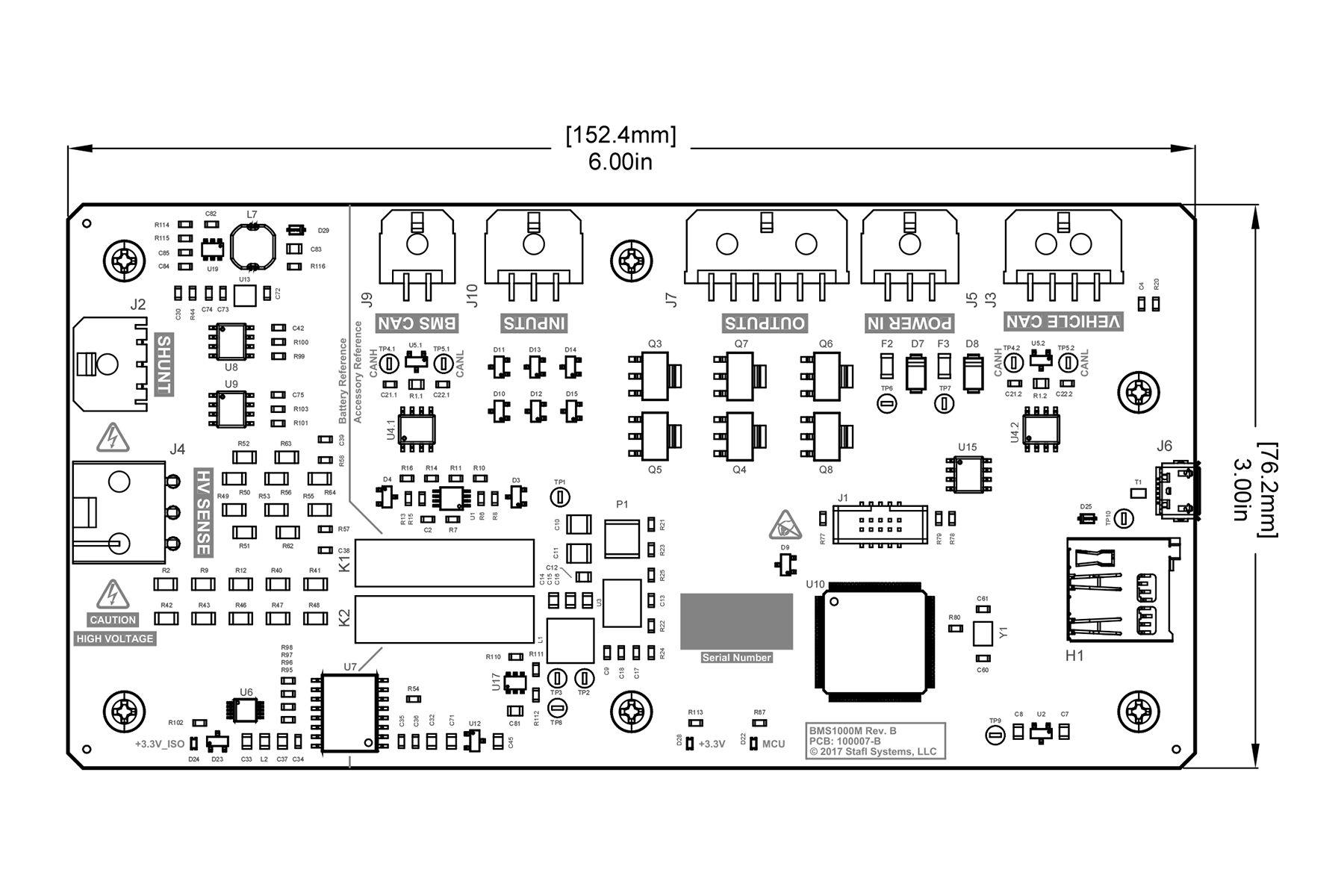

The Stafl Systems modular BMS1000 Series Battery Management System consists of one BMS Master Module and an application-specific number of BMS Monitor Modules.

1X Master BMS Unit

Communicates with outside system via CAN 2.0B

Manages pre-charging and contactors

Monitors pack voltages

1-64X Monitor BMS Units

Measures cell voltages and temperatures

Balances cells

Communicates with Master BMS via internal data link

precise engineering

Features

Scalable from 12 to 256 Series Cells

Temperature Sensor for Each Cell Group

Supports up to 1000V Systems

Low Steady State Cell Voltage Measurement Error (<2.0 mV)

Individual Cell Group Balancing Resistors

Externally Powered for Low Quiescent Battery Current

High Current Shunt Monitor Circuit for Accurate Pack Current Sensing

Pack Level Voltage Monitoring

Integrated Isolation Fault Monitor Circuit

SEE ALSO: BMS Product Family Brochure (PDF)

Typical System Diagram

COUNTLESS APPLICATIONS

hIGH VOLTAGE

While a vehicle’s power system sees a battery pack as a single, high-voltage battery — charging and discharging the entire battery pack at once — the battery control system must consider each battery’s condition independently.

LOW VOLTAGE

A proper system will continuously monitor important battery parameters for low voltage applications, while dealing with the varying power demands of the many aspects of operation and optimizing the usage of the battery.

stationary storage

The service life of a battery pack is tied to the weakest battery in the system. In the balancing process, each of the batteries within the string is maintained at optimal voltage levels, eliminating the ill-effects of improper charging.